Wire Composition

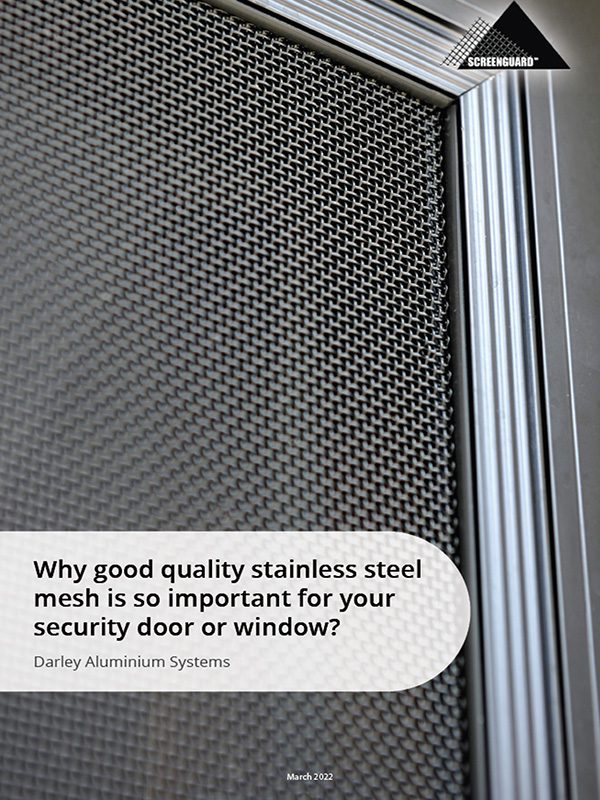

As you probably already know stainless steel mesh is made of intersecting columns of stainless steel wire. This type of mesh has been around for centuries and is used in a number of applications such as fencing, barricading, grills, sisters and metal safety gloves.

As mentioned previously, the type of marine grade stainless steel is an important factor to consider because of its chemical composition and marine grade 316 is considered the superior mesh because of its higher corrosion resistance.

With the increasing popularity of 316 marine grade mesh, it has never been more important to reassure customers of the quality of the mesh used in their security products. It is for this reason, Darley send samples of our screenguardmesh to third party laboratories to verify the chemical composition of our stainlesssteel mesh and ensure customers receive quality 316 grade stainless steel.

Another aspect that needs to be taken into consideration is the diameter of the wire used in the stainless steel mesh. In Australia, the two most common wire diameter sizes are 0.8mm and 0.9mm. Our ScreenGuard system uses wire with a diameter of 0.8mm. The same wire diameter has been used in the manufacturing of ScreenGuard mesh for over 15 years, offering consistent quality and appearance but also making it slightly challenging in the weaving process with the thicker wire being harder to weave.

As you probably already know stainless steel mesh is made of intersecting columns of stainless steel wire. This type of mesh has been around for centuries and is used in a number of applications such as fencing, barricading, grills, sifters

and metal safety gloves. As mentioned previously, the type of marine grade stainless steel is an important factor to consider because of its chemical composition; marine grade 316 is considered the superior mesh because of its higher corrosion resistance.

Another aspect that needs to be taken into consideration is the diameter of the wire used in the stainless steel mesh. In

Australia, the two most common wire diameter sizes are 0.8mm for 316 marine grade mesh and 0.9mm for 304 marine grade mesh.

Our ScreenGuard system uses wire with a diameter of 0.8mm. The same wire diameter has been used in the manufacturing of ScreenGuard mesh for over 15 years, offering consistent quality and appearance but also making it slightly challenging in the weaving process with thicker wire being harder to weave. The tensile strength of the individual steel wire is an important contributor to the strength of the stainless steel mesh.

Tensile strength is the measurement of force the wire can withstand before it breaks. The stainless steel mesh used in the ScreenGuard system has a tensile strength of 850 – 900 pascals. Meaning it can bear a heavy load before breaking

– making it an ideal barrier in extreme weather conditions. It’s interesting to note – it is possible to increase the tensile strength of a single strand of stainlesssteel wire. This process is referred to as quenching and involves applying a heat treatment to the wire, followed by rapid cooling – which alters its chemical properties and increases or decreases its tensile strength.